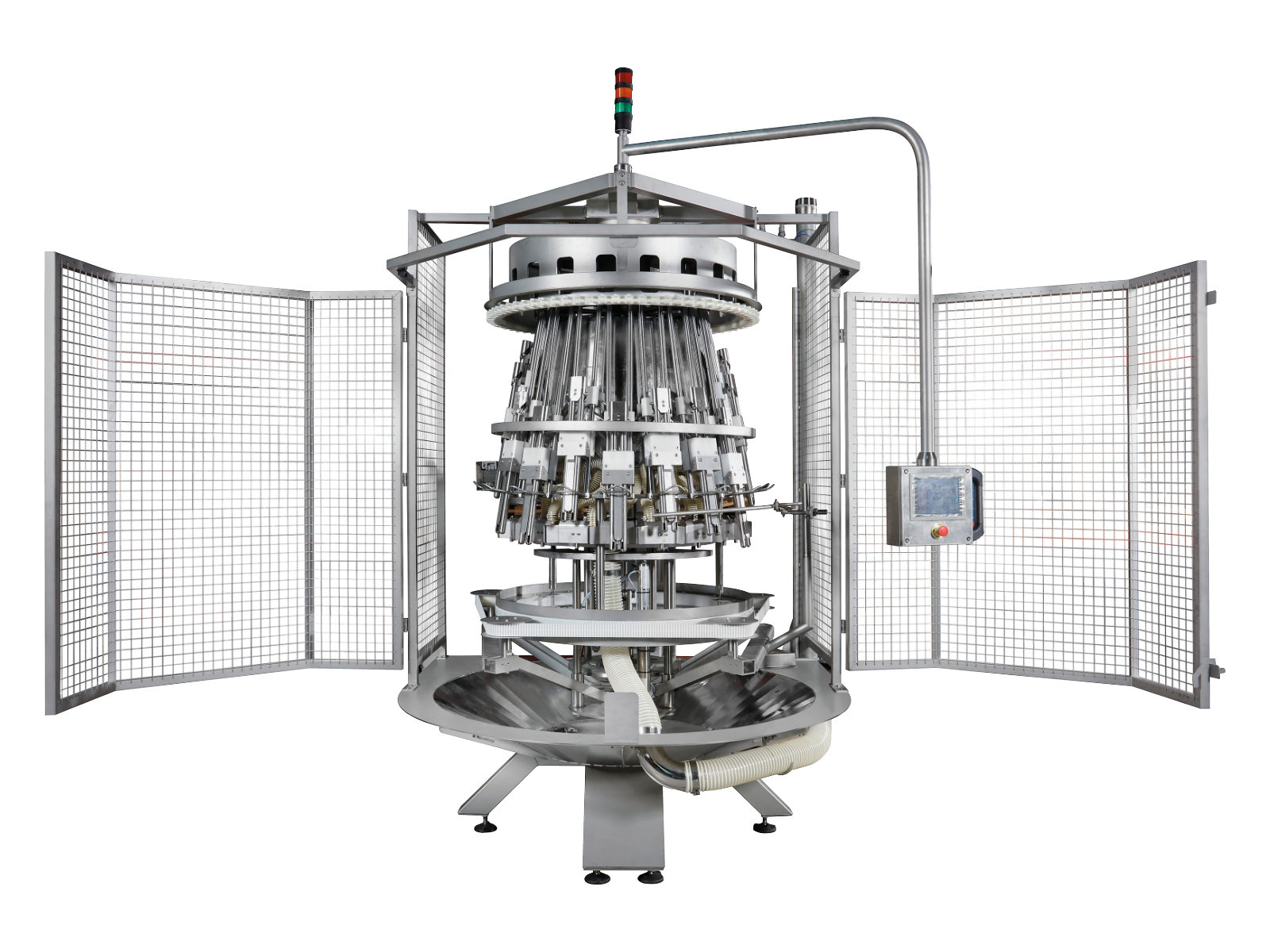

Duck opening machine

- Optimized cleaning

- "HYGIE" range

- Personalized program

Description

The duck opening machine is necessary in order to ensure the good running of the following steps of the evisceration process, particularly to improve the introduction of the evisceration tool.

Made in stainless steel, the duck opening machine integrates an electric adjustment system that simplifies machine settings between batches. (programs)

The duck opening machine is part of the equipment range of the “HYGIE” line. Our engineering department has studied this equipment in order to meet hygiene requirements on the poultry market.

The opening machine has been developed in a hygienic design with a refined frame allowing excellent cleaning by making the central shaft easily accessible to the maintenance teams of slaughterhouses.

The opening machine also has an integrated cleaning ramp which allows the lubrification of the columns during the operation of the machine, but also the pre-rinse of the tools to guarantee optimal hygiene.

All these improvements make the duck opening machine an efficient and hygienic equipment for optimized evisceration of your ducks.

The duck opening machine is available in several configurations according to your production capacity.

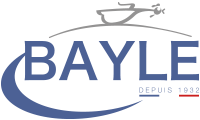

Automatic eviscerator harvester

- Smart machine

- Easy adjustement

- Optimized cleaning

- All types of duck

Description

The BAYLE duck eviscerator is a multi-post carousel that automatically removes the viscera pack of the ducks and deposits it on a transport belt synchronized with the poultry.

Thanks to its unique and innovative design, the duck eviscerator is equipped with a compensation system to absorb dismorphism in the same batch. This innovative system allows optimization of evisceration results while preserving the quality of the duck carcass, but also has the capacity to treat all types of ducks.

Hygiene is also optimized by the absence of contact between the intestine pack and poultry, but also by the development of a high-pressure cleaning system for the tools by nozzles that ensure continuous cleaning of the tools in order to reduce the risk of cross-contamination.

Our automatic duck eviscerator is also equipped with an HCI system allowing a simplified machine adjustment and a formula type adjustment via an intuitive and easy-to-use screen.

The automatic duck eviscerator is compatible with our Bayle Smart Control supervision system.

Duck cropper

- Optimized cleaning

- Formula adjustment

- All types of poultry

Description

The duck cropper intervenes in the duck evisceration process to remove the crops of palmipeds while preserving the quality of the poultry and their skin.

The duck cropper by its design has an important stroke of its tools allowing it to efficiently remove the crop of all types of poultry, including big poultry. The BAYLE duck cropper has the biggest stroke tools of the palmiped market.

Designed to meet hygiene recommendations on the slaughterhouse, the cropper is equipped with a cleaning system to ensure a perfect cleaning of the tools. Equipped with 3 cleaning brushes placed in 2 strategic positions, the cropper ensures an optimized and efficient cleaning of cropping tools.

The DJBC also has a “water+air” injection function placed at the end of each tool, thanks to this, the skin of the neck is taken off so that it can harpoon the crops alone.

The cropper is equipped with an electronic settings system allowing simple and intuitive adjustment of the machine configuration. The settings are made in the form of a selection of formula that are finely adjustable in production.

Duck Neck opening machine

- Hygienic design

- Optimized adjustements

- Automatic process

Description

The duck neck opening machine is used in the duck evisceration process to split the neck skin without marking it.

Designed on a tubular structure with integrated motor and cables, the FPCC is a hygienic design machine that is part of the “HYGIE” equipment line. Featuring one of the most efficient surface finishes on the market, the duck neck opening machine ensures excellent cleanability to meet the hygiene standard that is now essential on the slaughter units.

Fully automatic machine, the FPCC is adjustable in production thanks to guides that guarantee a high quality of fit. All machine configurations are adjustable by its simple and intuitive user interface.

The duck neck opening machine is compatible with our Bayle Smart Control supervision system.

Head & Beak cutter

- Automation of the process

- Formula type settings

- Controlled bulk

Description

The Head and Beak cutter is a part of the automatic duck evisceration process which aims to successively separate the beaks and then the heads of the ducks in order to treat them in the following stage of the process.

The Beak and head cutter has been designed and developed on a refined stainless steel frame in order to guarantee easy cleaning as well as a controlled bulk.

The CBAT is available in several configurations that fit your working methods. It allows the cutting of the beak by motorized blade and the evacuation of them on a special transport belt for the treatment of duck tongue in a later stage.

The heads are snipped by a fixed stainless steel blade. They are also evacuated on a second transport belt for their valorization.

In order to guarantee a good hygiene, the tools are cleaned by water spray nozzles

The CBAT is a fully automatic machine that integrates an electric cabinet. It is compatible with our Bayle Smart Control supervision system.

Duck neck breaker

- Single design without operationf jerks

- Mechanical robustness

- Hygienic tools

Description

Bayle has innovated and developped the most effective neck breaker in the duck market.

The duck neck breaker allows the removal of the neck while leaving the skin of the palmipeds intact.

Its cracking principle allows breaking of the bones without leaving sharp points, thus reducing the risk of punctures of the packages.

Our R&D department has developed a unique neck breaker. Designed without central shaft and with a fully hollow frame, all the components have been placed outside to obtain an optimized maintenance machine and a good cleanability. The hygiene of the product is also increased by the absence of friction of the poultry on guides or on the machine, which considerably reduces the risk of bacterial contamination.

Its ingenious mechanical design makes the neck breaker a piece of equipment of unequaled robustness. Its maintenance is optimized by the development of high-performance and hard-wearing tools.

Equipped with an intuitive HCI system based on pictograms, the neck breaker has adjustable settings

The duck neck breaker is compatible with our Bayle Smart Control supervision system.

Duck Inside / Outside washer

- Optimized cleaning

- Formula settings

- "HYGIE" range

Description

The LIEC is an inside/outside duck washer that is placed in the last stages of the duck evisceration process.

Designed to improve the hygiene of your slaughtherhouse, the LIEC has an internal and external cleaning action of ducks after their evisceration in order to obtain perfectly hygienic products.

Made in stainless steel, the LIEC is part of “HYGIE” range, which thanks to its technical developments guarantees a good cleanability.

Equipped with pre-registered electrical settings as a formula, the LIEC allows a quick and easy adjustment of the machine between your batches.

Available in several configurations to suit your needs according to your productions rates, the LIEC is recommended for units up to 6 000/h

Duck lung remover

- Optimized hygiene

- Low power consumption

- Multi-product efficiency

Description

The lung remover represents the last stage of the duck evisceration process. The APC removes the lungs from the ducks by sucking them out by vacuum while preserving the quality of the finished product.

The duck lung remover is part of the “HYGIE” equipment line, So it has a hygienic machine design that is defined by several features:

- First, the APC has a design with easy access to the delivery feeder tank, which thanks to its opening allows high pressure cleaning with foam. This, combined with a visual check by cleaning teams, ensures an optimal hygiene quality.

- The lung remover is also equipped with a self-cleaning cycle of the machine suction circuits. Thanks to the development of a powerful rinsing system, the tools are effectively cleaned to minimize the risk of bacterial contamination.

In an approach to responsible consumption of our energies, R&D has developed a system for triggering vacuum by detecting poultry on tools. This innovation allows controlled and responsible energy consumption, but also ensures a better quality of suction when removing the lungs from the ducks.

The lungs remover is available in several configurations, this machine is effective on Barbary duck and Pekin duck

Do you want to know more about it?

Contact our sales team

Our sales department is at our disposal to answer your questions. We have an agents network around the world, so do not hesitate to contact them to speak of your project.